What if robots could simply disappear when you're done with them? Our groundbreaking research introduces soft robotic systems made from sustainable materials that can perform complex tasks and then naturally decompose.

From Cotton to Cellulose: Material Science

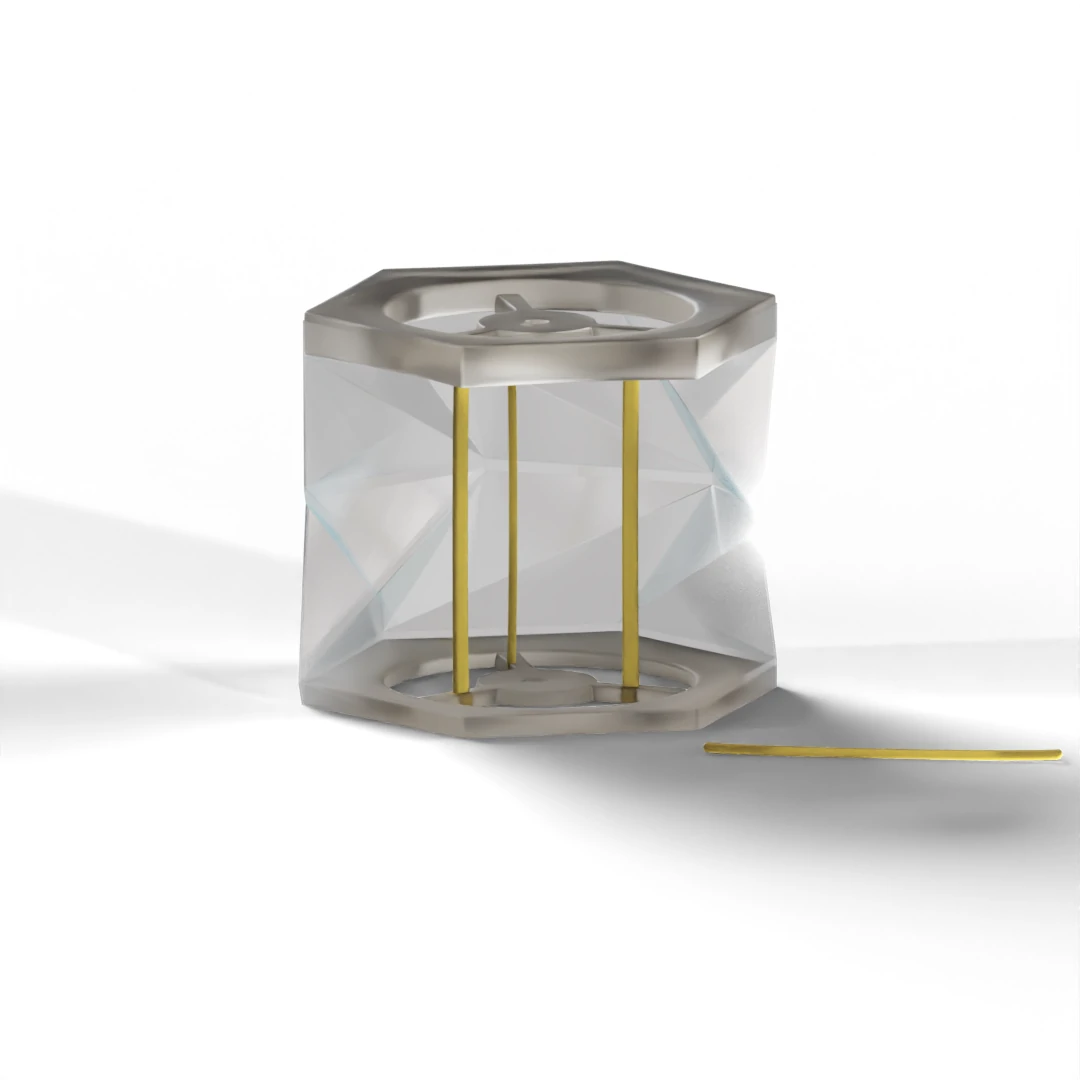

We developed mechanically robust plasticized cellulose films using glycerol as a natural plasticizer. Glycerol molecules form hydrogen bonds with cellulose chains, reducing the strong inter-chain interactions and creating a more flexible material ideal for origami folding.

Mechanical Properties Comparison

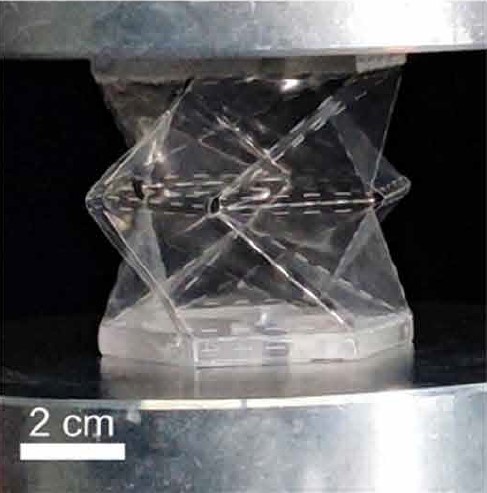

The plasticized cellulose films exhibit an ideal balance of strength and flexibility. With a tensile strength of 48±3 MPa (vs. 86±5 MPa for pristine cellulose) and elongation at break of 43±4% (vs. 21±2% for pristine), these films can withstand repeated folding without fracture.

Sustainable Material Processing

Cellulose Dissolution

Cotton linter pulp was dissolved in an aqueous NaOH/urea solvent system. This environmentally friendly approach eliminates the need for toxic organic solvents typically used in conventional polymer processing, aligning with our sustainability goals.

Regeneration Process

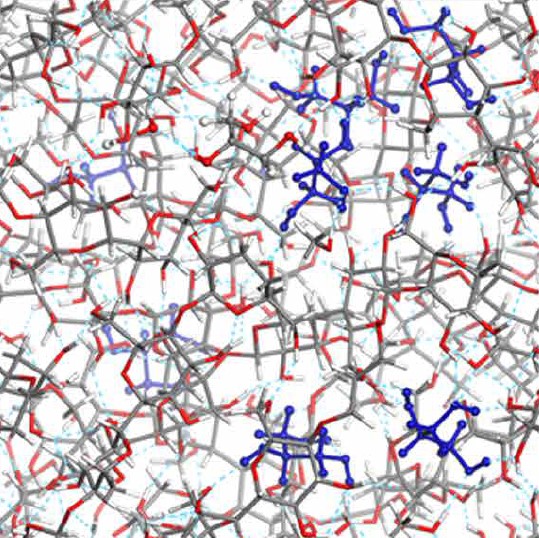

The cellulose solution was cast and immersed in deionized water for regeneration. During this process, cellulose chains self-assemble into nanofibers and cellulose II crystallite hydrates, forming a physically cross-linked network through hydrogen bonding and chain entanglements.

Glycerol Plasticization

Cellulose hydrogels were treated with glycerol, a natural, biodegradable plasticizer. Glycerol molecules disrupt the strong hydrogen bonding between cellulose chains, enhancing flexibility and toughness. This crucial step enables the material to withstand repeated folding without fracture at the creases.

Access the Full Research

Interested in learning more about this innovative approach to sustainable robotics? Read the complete research paper for comprehensive details on materials, fabrication, performance analysis, and future directions.